Lifting Chain Inspection Checklist

Lifting Gear – Chain and Wire Rope Sling Inspection Checklist

The information provided on this lifting chain inspection checklist page has been curated for guidance purposes only and is not to be construed as approved custom and practice. No action should be taken solely on the information outlined in this content. Please consult the Lifting Equipment Engineers Association (LEEA) for the latest recommended working practices.

In addition, you should also reference the following publications available from the Health and Safety Executive:

In addition, you should also reference the following publications available from the Health and Safety Executive:

Thorough Examination of Lifting Equipment

When it comes to lifting, the best safeguard against personal injury fatalities and damage to property is frequent and careful inspection of lifting equipment .

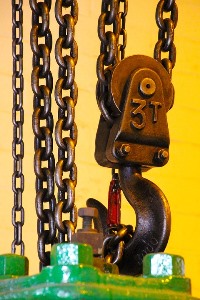

In doing so, organisations are encouraged to be just as vigilant with equipment that is used on the end of a lifting hook as well as the hoists and winches themselves above the lifting hook.In this respect, inspection of wire rope and chain slings are subjected to same scrutiny as hoists and with a 3 part inspection carried out by qualified and highly trained technicians using a comprehensive LOLER checklist template.

Lifting Equipment Checklist Template

Inspections of wire rope slings should be carried out before each lift and begin with visual inspections covering the whole sling ensuring that all surface areas ore completely visible by removing all contamination and dirt from wire.

Wire rope slings should not be inspected by running bare hands over theme because the presence of a broken wire could result in a serious puncture wound.

Examinations should be thorough with particular emphasis on the following checklist:

- Doglegs, bird caging and kinking

- Broken wires

- Severe wear from scraping and abrasion

- Heat damage

- Corrosion of wire rope and fittings

- Missing or illegible ID tags

- Damaged fittings – worn, cracked or ill fitting

If inspectors detect any of the above signs of damage, the affected sling needs to be removed from active service immediately and destroyed so it cannot be used further. Damaged slings should never be repaired and put back into service

Lifting Sling Inspection Checklist

The same critical lifting chain inspection vigilance employed when inspecting wire rope slings should also be utilised out with chain slings inspections also.

This makes sense because a thorough lifting chain inspection checklist and lifting sling inspection checklist inspection regime will help keep employees safe, extend the working life of the lifting slings and ensure compliance with legal regulations.

Chain slings should be inspected using a lifting sling inspection checklist before every lift and also be subject to periodical thorough examinations of lifting equipment by a competent person. The relative frequency of chain sling inspections is driven by several factors including the nature and type of lifts being undertaken, how often the slings are being used, how severe the operating environment is as well as the average anticipated “sling life” experienced for similar operations.

Employers are responsible for ensuring that a fully trained and highly experienced “competent person” inspects all slings and other lifting equipment in accordance with LOLER and PUWER regulations. Competent persons can be company employees or specialist third party inspection service providers.

Employers are responsible for ensuring that a fully trained and highly experienced “competent person” inspects all slings and other lifting equipment in accordance with LOLER and PUWER regulations. Competent persons can be company employees or specialist third party inspection service providers.

The LOLER regulations stipulate that regular inspections should occur while the sling is in service and that a “thorough examination” to be carried out at the intervals specified by LOLER i.e. every 6 or 12 months, depending on the type of lifting equipment. In addition, organisations are mandated to keep accurate records of thorough inspections conducted throughout the sling’s service lifespan.

Lifting Equipment Checklist Template and Lifting Accessories Checklist Template

However, the sever nature of the operating conditions and increased usage may warrant more frequent thorough chain sling inspections than specified by LOLER.

In such circumstances, inspections of wire rope and chain slings may warrant examinations before each lifting operation or factory shift. This is especially true if any change in the type of lifting operation especially if it more onerous. In such situations, inspectors could conduct immediate visual examinations using an appropriate lifting sling inspection checklist and decide to remove a sling from operational service if it is suspect in any way.

In operating environments where extremely heavy usage is the norm, organisations should not rely on one inspection in a 24 hour period. Excessive heat, severe angles, shock loads and sharp edges on loads can result in serious damage and visual inspections should be carried out before each lift is made during the day or shift.

Furthermore, an organisation must have very stringent procedures governing the withdrawal from service and destruction of unserviceable slings and other lifting equipment.